Understand the functionalities and limitations of forklifts

Respect the functionalities and limitations of the forklifts!

The forklifts are industrial equipment that have specific functionalities and limitations, most often displayed even on the metal body. This is the reason why, in general, they are not seen outside distribution centers, warehouses or production centers. The forklifts have different attributes that must be known and understood by the operator in order not to overload the equipment during work. These attributes can be defined as follows:

- Tendency to become unstable

- Transport of heavy loads at a great distance from the ground

- Traction on the front wheels, but steering control on the rear wheels

- Change of steps during the transport of a load

- Low longitudinal stability when the load is high

If you sum up the general conditions of the space in which the forklift operates with the attributes of the forklift, you will find that the level of wear increases and, with it, the degree of danger increases. Generally, forklift operators need to be concerned about the following:

- Dangerous environmental conditions

- Uninsured loads with cables

- Uneven, rough or inclined surfaces

- Blind spots

- Narrow color

- Pedestrian traffic

If precautionary measures are not taken for all the aspects presented above, the operator is at enormous risk, both he and the people around him.

Safety systems are not necessarily a solution

Many companies have different safety systems that reduce the chances of an accident in the warehouse, but this is not the only solution you can stop. There are many cases where accidents have occurred in places where different safety systems were installed. What we want to highlight is the fact that, regardless of the number of safety systems, the operator of the forklift truck must be prepared and always understand the dangers to be exposed if they work in an unsafe environment. An uncertain environment may include:

- Unauthorized transport of passengers

- Incorrect and improper loading of loads

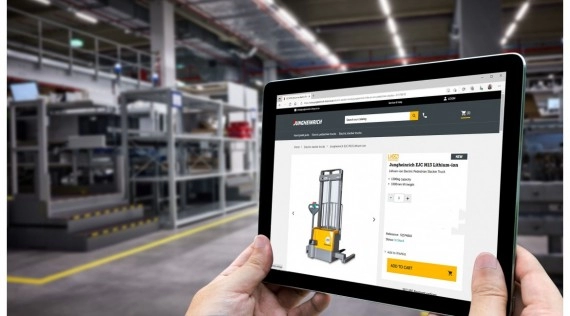

- Speeding

Rare, incomplete or superficial maintenance also increases the risk of an employee being involved in an accident at work, precisely because of this, maintenance must be done periodically and with great care. The equipment must always be in optimum operating conditions so as not to cause any accidents, and operators and other employees must always understand and respect the functionalities and limitations of the forklifts. We are also waiting for you next week on the Jungheinrich blog for new information on forklifts.