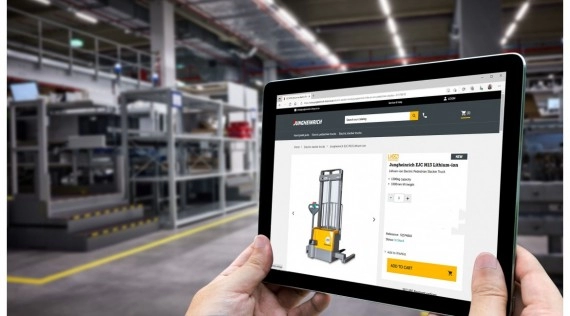

Electric or manual pallet truck?

All warehouses and stores need machines to help manage their goods. Of all the machines, pallet trucks are among the most used, because they are easy to handle and take up very little space. In addition, the staff does not need extensive training to handle them, they are less dangerous and easily fit any freight truck.

The pallet trucks are divided into two main categories: the electric and the manually operated ones. In today's article we will focus a little on the two models to point out the main advantages and disadvantages, but also which is the best solution.

Electric pallet trucks are twice as large as those that operate manually, but have a lifting capacity of up to 30%. Their main advantage is that the operator does not have to manually pull the heavy load or pump the handle to lift the load.

The obvious disadvantage is that the electric pallet trucks must be charged every 8-12 hours of operation, otherwise they will not be able to operate and the operators will not be able to manually move the pallet truck due to its large size and weight.

Electric pallet trucks are very useful in warehouses where distances are large, because operators would make too much effort to move pallets manually from one place to another.

On the other hand, accidents at the workplace can be significantly reduced by the exclusive use of electric pallet trucks. The best solution is for the warehouse or store to have both types of pallet trucks to use each one in the right context.

We look forward to seeing you next week on our blog to find out more about machinery and workplace safety. Visit us on Facebook and www.jungheinrich.ro.